Design Your own

Raw LiFePO4 Cell Battery Solar power System!

This is a complete system solution complete with:

- BMS Protection Features (over/under voltage/over-current/balancing)

- Low Temperature Cut-off

- Programmable Charge/Discharge Bandwidth Settings

- Matched LiFePO4 Cells that will last for ages

- Low-voltage disconnect options for large inverters

- Make it as large as you want! Power a small village or home if you want

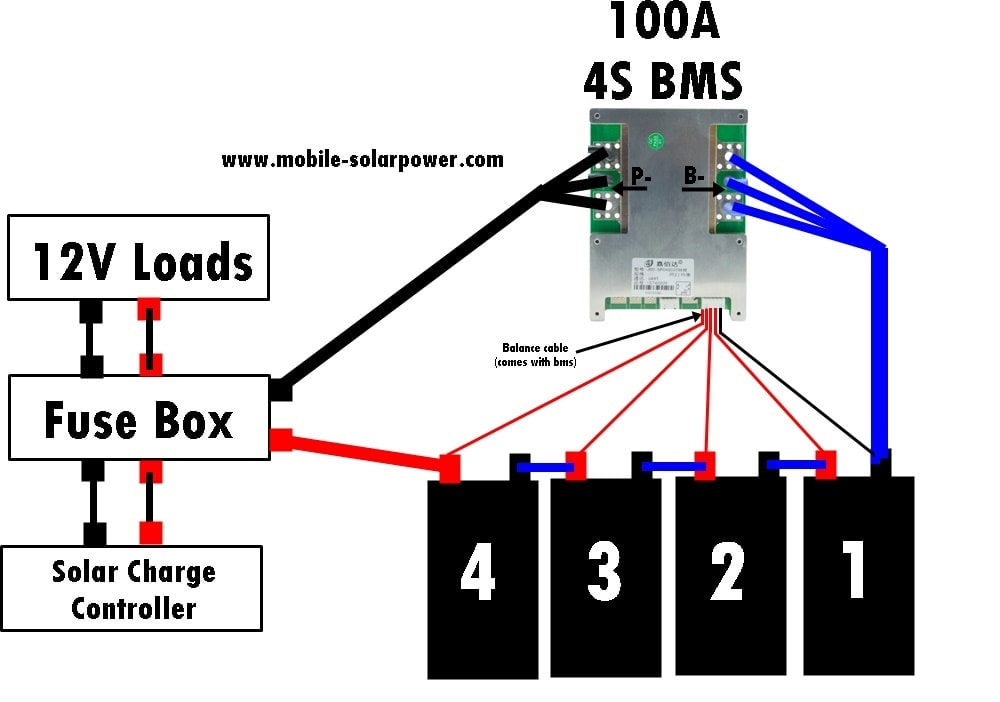

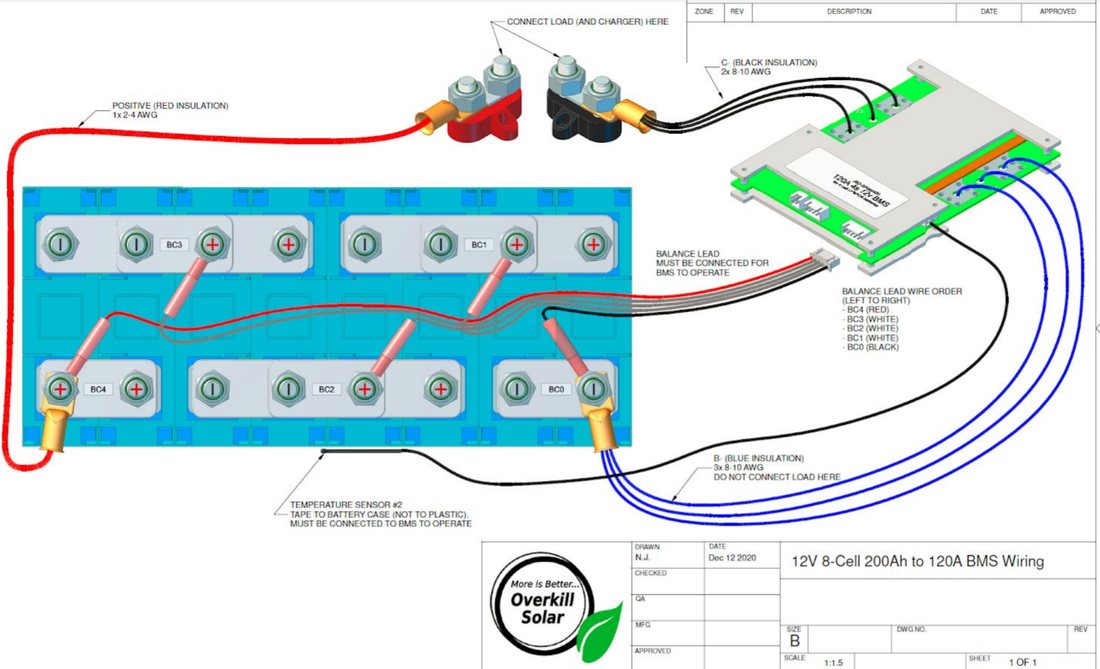

A basic 12V BMS Protected LiFePO4 System Schematic:

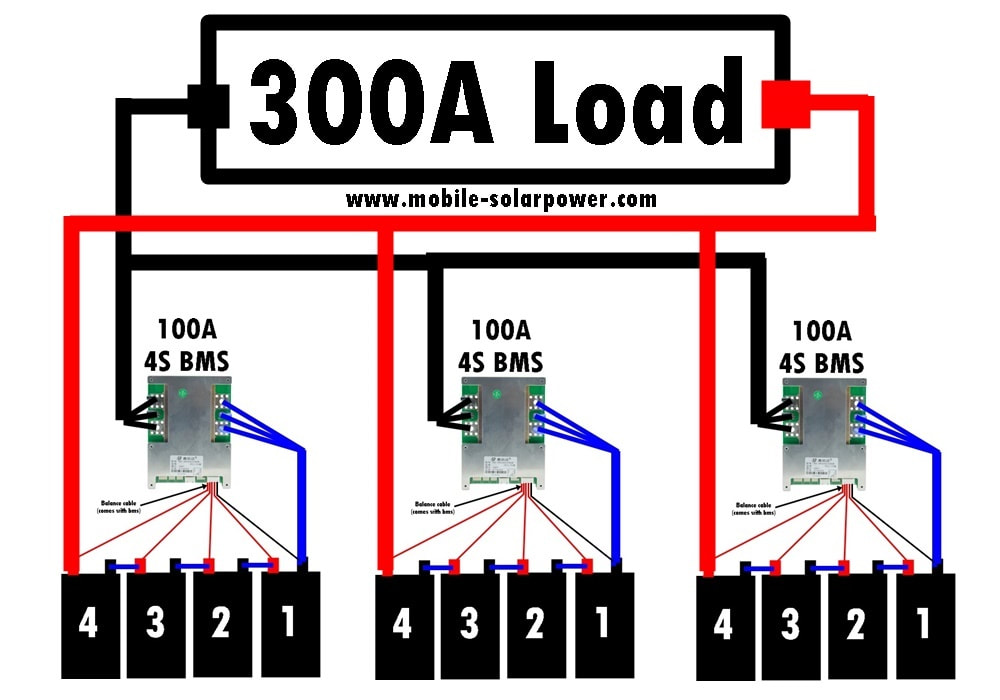

If a single BMS cannot handle the current required by your loads,

Make 3X individual batteries and put them in parallel:

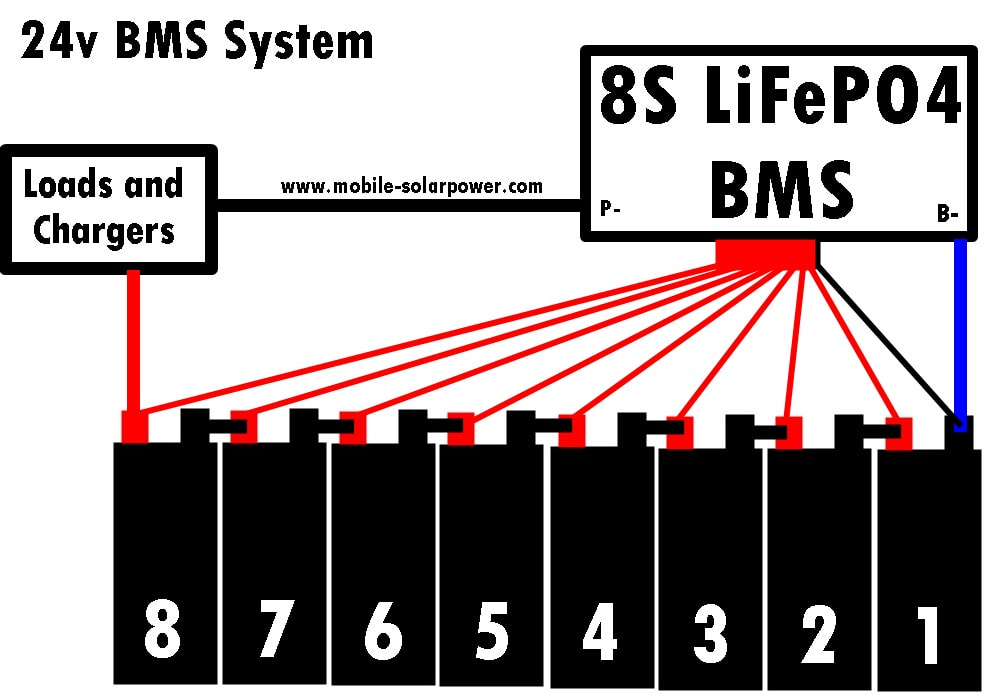

If you wish to run a LARGE inverter (or any load

larger than 2000W), build a 24v/48v System:

Running a solar power system at 12V is pretty illogical when you need to run large inverters. You will spend a TON of money on BMS/Wire/OCPD etc. So to save yourself a lot of time and money, build a higher voltage battery bank. This will allow you to run a massive inverter with a single 100A BMS. Let's think about this for a second...

You will also save a ton of money in wire costs alone (hundreds of dollars worth usually). So if you are powering any load that is larger than 2000W, run a higher voltage battery. You will save yourself a lot of time and money.

- If you run 12V, a 100A BMS can run a 1,200W load max

- If you run 24v, a 100A BMS can run a 2,400W load max

- If you run 48v, a 100A BMS can run a 4,800W load max!

You will also save a ton of money in wire costs alone (hundreds of dollars worth usually). So if you are powering any load that is larger than 2000W, run a higher voltage battery. You will save yourself a lot of time and money.

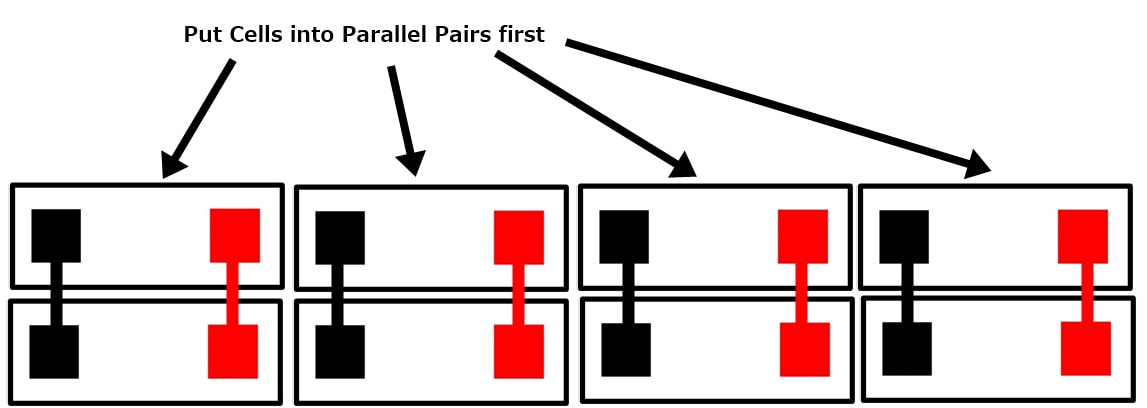

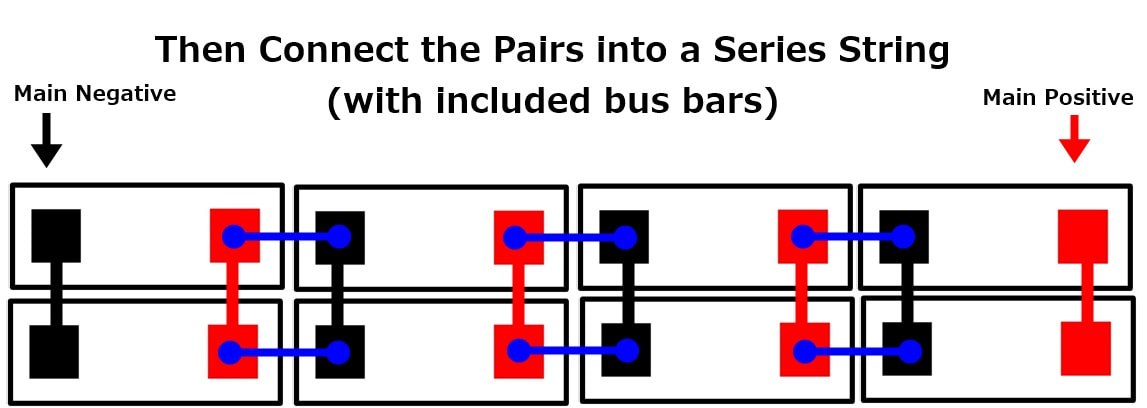

How to configure cells in a large battery Bank

If you are building a large battery bank, you should buy larger cells. If the largest size cells cannot do the job, you will need to combine cells in parallel first, then connect them in series. This will allow you to build and manage a large battery bank with a single BMS.

When you parallel your cells, they need to be nearly the same voltage. If you buy brand-new cells, they will come at the same voltage and you can wire them up like this:

When you parallel your cells, they need to be nearly the same voltage. If you buy brand-new cells, they will come at the same voltage and you can wire them up like this:

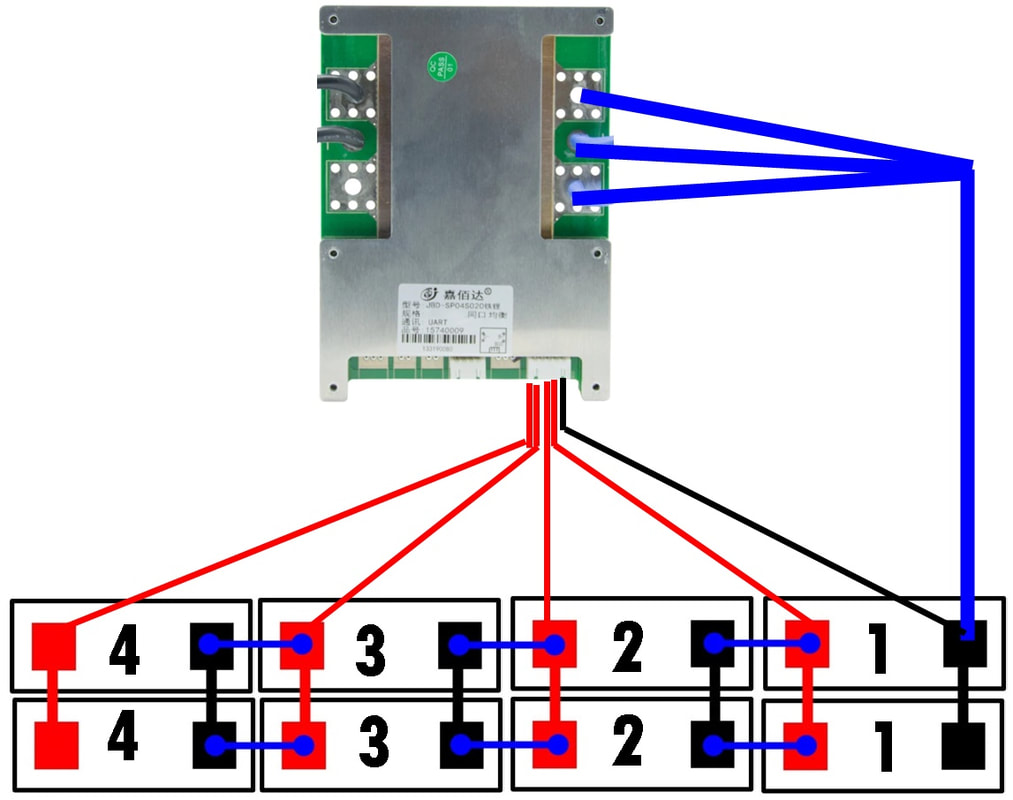

Then add a single BMS to manage all the cells:

Recommended Charge Profile:

12V LiFePO4 Battery w/ BMS:

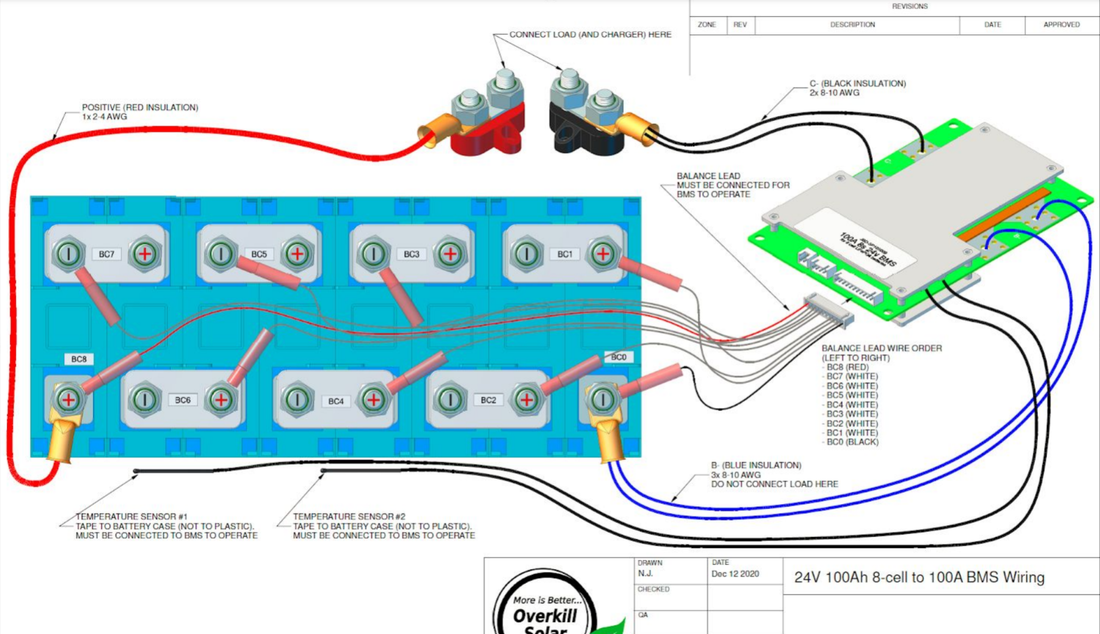

24V LiFePO4 Battery w/ BMS

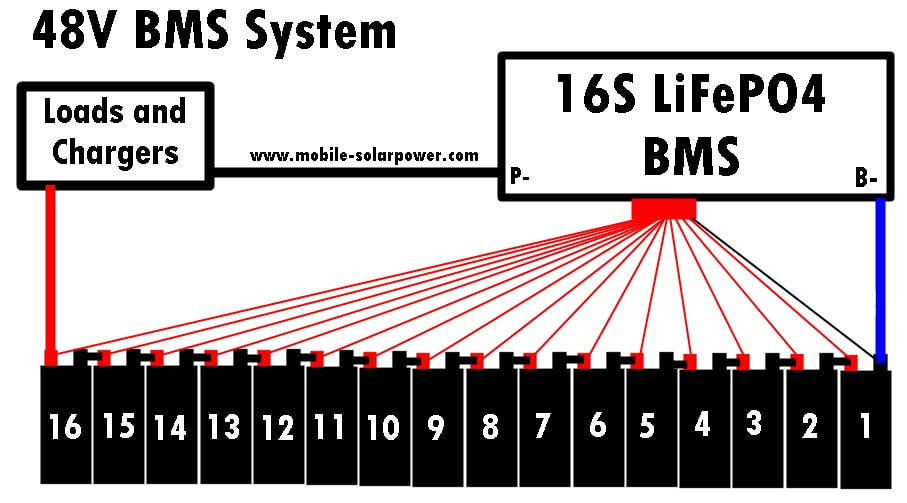

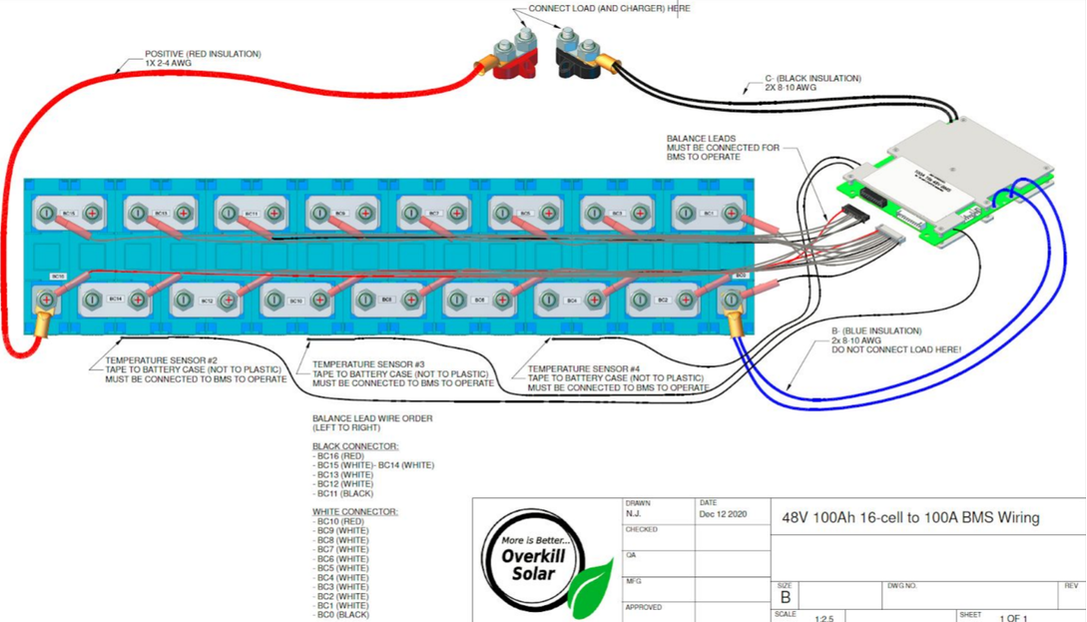

48V LiFePO4 Battery w/ BMS

If you are using a BMS and wish to manually cycle up to 90% SOC:

If you want your LiFePO4 cells to last a long time, you can set your absorption to Victron's custom LiFePO4 charge profile recommendation:

- Absorption: 14.5V

- Float: 13.6V

- Inverter Cut-off: 10.7V-12V (depending on size of load and voltage drop etc)

24V LiFePO4 Battery w/ BMS

- Absorption: 29V

- Float: 27.2V

- Inverter Cut-off: 21.4V-24V

48V LiFePO4 Battery w/ BMS

- Absorption: 58V

- Float: 54.4V

- Inverter Cut-off: 42.8V-48V

- Absorption: 3.625V

- Float: 3.4V

- Low voltage disconnect for capacity testing: 2.5V

If you are using a BMS and wish to manually cycle up to 90% SOC:

- Do a discharge capacity test with a shunt. Record capacity in watt hours.

- Charge slowly up to 90% SOC (take capacity Wh figure and multiple by .9), and while charging, record the voltage right when it hits 90% SOC

- Set the absorption for all chargers in system to the voltage you recorded in step 2

If you want your LiFePO4 cells to last a long time, you can set your absorption to Victron's custom LiFePO4 charge profile recommendation:

- 12V Battery: 14.1V

- 24V Battery: 28.2V

- 48V Battery: 56.4V